Performance of the year

In 2013, contractors injury frequency rate continued to follow a positive trend (down by 81.9% from 2012). Employees injury frequency rate remained unchanged.

In 2013 emissions of greenhouse gas and other emissions in the atmosphere improved from 2012 following the interruption of production at the Porto Torres site in the conversion phase. Further reductions were registered, particularly at the Mantova site for NOx, and NMVOC as well as at the Dunkerque site for SOx and NMVOC. Recycled/reused water rate improved, up to 86.2%.

In 2013, as part of the Product Stewardship, Versalis realized a specific database called Athos (Advanced tool for the handling of substances) which collects all the information necessary for the safe management, for employees and for the environment, of chemical products processed and utilized at Versalis sites.

In 2013 adjusted net loss amounted to €338 million with a decline of €57 million from 2012, due to a sharp decrease of cracker margins reported in the first half of 2012.

Sales of petrochemical products were 3,785 ktonnes, down by 168 ktonnes or 4.2% from 2012, due to decline in consumptions.

Petrochemical production volumes were 5,817 ktonnes, decreasing by 273 ktonnes or 4.5% from 2012, due to declining demand in all businesses. In particular, the steepest decline was reported in elastomers and polyethylene.

In 2013 overall expenditure in R&D amounted to approximately €39 million in line with the previous year. 10 patent applications were filed, one of which jointly with E&P.

Expansion on international markets

As part of the expansion strategy in bioplastic sector and diversification from the commodity business, Versalis signed strategic partnerships with major operators in the field of biotechnology and rubber:

- with Genomatica, for the establishment of a technology joint venture for bio-based butadiene production from non-food biomass. The resulting process will be licensed across Europe, Asia and Africa by the newly-created joint venture. Versalis will invest over $20 million in the development of process technologies and aims to be the first to license the process and build commercial plants;

- with Pirelli, a Memorandum of Understanding for joint research project for the use of guayule-based natural rubber in tyre production;

- with Yulex Corporation, an agricultural-based biomaterials company, for a project of guayule-based biorubber production and a launch of industrial production complex in Southern Europe. The partnership will cover the entire manufacturing chain. Versalis will manufacture materials for various applications, with a final goal of the optimization of the productive process in the tyre industry;

- with South Korean company Lotte Chemical, Versalis established a 50:50 joint venture, while with Malaysian company Petronas, Versalis signed a shareholders agreement. The agreements concern the development of joint production of styrene and elastomers, as part of the expansion process in the growing South-East Asian markets;

- with Neville Venture, Versalis signed an agreement of strategic partnership for the production of hydrocarbon resins at the Priolo plant and finalized a licence agreement related to the resins production for various applications such as adhesives, inks, coatings and rubber;

- with Elevance Renewable Sciences Inc., a United States chemical company, specialized in production of chemicals from vegetable oils, with a significant value added, Versalis signed a Memorandum of Understanding (MoU) for establishing a strategic partnership, in order to jointly develop and scale a new technology for a production from vegetable oils, aiming at developing and scaling of new catalysts. The market applications of the future production will be specialties with a significant added value such as personal care products, detergents and cleaners, bio-lubricants and oilfield chemicals.

Green Chemistry development

In the field of Green Chemistry, Versalis continued with the requalification the Porto Torres hub, in order to replace the traditional activities of the site with activities characterised by significant future growth perspectives, by realizing the products with an elevated biodegradability and/or produced from row materials obtained from renewable sources. In 2013, Versalis completed the initiatives of restructuration and reorganization of the distribution network and storage at the Matrìca plant.

In February 2014, Versalis reached an important agreement on the project of transformation and relaunch of the Porto Marghera site to redesign production facilities and regain competitiveness. Versalis expects to invest €200 million in Porto Marghera focused on the optimisation and reorganisation of cracker utilities, with significant energy savings, and on the new initiative of green chemistry.

Activities

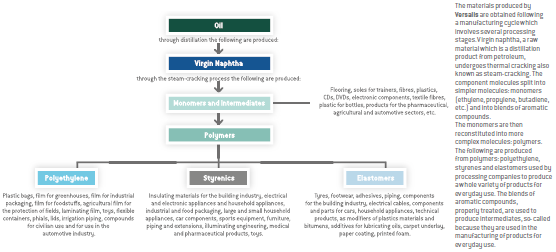

Eni trough Versalis performs activities of production and marketing of petrochemical products (basic petrochemicals and polymers), leveraging on a wide range of proprietary technologies, advanced production facilities, as well as a large and efficient retail network present in 18 European countries.

Versalis’ portfolio of patents and proprietary technologies covers the whole field of basic petrochemicals and polymers: phenol and its derivatives, polyethylene, styrenes and elastomers as well as catalysts and special chemical products.

As a producer of intermediates, all types of polyethylene and a wide range of elastomers/latices and of the complete line of styrenic products, Versalis continues in the development of its proprietary technologies supported by the experience it gained in production and R&D. This approach favoured the optimization of the design of equipment and plants, of their performance, of proprietary catalysts and other products that allowed it to achieve excellence in all technologies in the specific business areas in order to compete in markets worldwide. A key role is played by the most innovative proprietary catalysts, particularly those based on zeolites developed by Versalis as building blocks of some of its most advanced technologies and available worldwide.

The principal objective of basic petrochemicals is granting the adequate availability of monomers (ethylene, butadiene and benzene) covering the needs of further production processes: in particular olefins production is strictly linked with the polyethylene and elastomers business, aromatics grant the benzene availability necessary to produce intermediate products used in the production of resins, artificial fibres and polystyrene. In polymers business Versalis is one of the most relevant European producers of elastomers, where it is present in almost all the relevant sectors (in particular, in the automotive industry), polystyrene and polyethylene, whose most relevant use is in flexible packaging.

The activities of Petrochemical division are mainly concentrated in Italy (Brindisi, Ferrara, Gela, Mantova, Porto Marghera, Porto Torres, Priolo, Ragusa, Ravenna, Sarroch, Settimo Milanese) and Western Europe, in France (Dunkirk), Germany (Oberhausen), the United Kingdom (Grangemouth, Hythe), Portugal (Neiva) and Hungary (Szàzhalombatta).