Refining

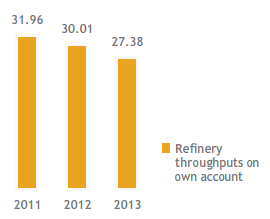

In 2013, refining throughputs were 27.38 mmtonnes, down by 2.63 mmtonnes, or 8.8% from 2012. In Italy, processed volumes decreased by 9.4% from 2012, due to the planned shutdown of the Venice Refinery following the Green Refinery project and in all the remaining plants due to a downsizing of productive assets in relation to declinining refining margins. Outside Italy, Eni’s refining throughputs (4.82 mmtonnes) decreased by 5.9% (down approximately 302 ktonnes) mainly reflecting the shutdown at the Kralupy Refinery in the Czech Republic for maintenance and lower throughputs in order to mitigate the negative impact of lower refining margins.

Total throughputs in wholly-owned refineries were 18.99 mmtonnes, down by 1.85 mmtonnes (down 8.9%) from 2012 determining a refinery utilization rate of 66%, declining by 6 percentage points from 2012, reflecting the unfavorable scenario. Approximately 23.7% of processed crude was supplied by Eni’s Exploration & Production segment, representing a 0.9 percentage points increase from 2012 (22.8%).

|

Availability of refined products |

|||||

|

|

|

|

|

|

|

|

(mmtonnes) |

2011 |

2012 |

2013 |

Change |

% Ch. |

|

ITALY |

|

|

|

|

|

|

At wholly-owned refineries |

22.75 |

20.84 |

18.99 |

(1.85) |

(8.9) |

|

Less input on account of third parties |

(0.49) |

(0.47) |

(0.57) |

(0.10) |

(21.3) |

|

At affiliated refineries |

4.74 |

4.52 |

4.14 |

(0.38) |

(8.4) |

|

Refinery throughputs on own account |

27.00 |

24.89 |

22.56 |

(2.33) |

(9.4) |

|

Consumption and losses |

(1.55) |

(1.34) |

(1.23) |

0.11 |

8.2 |

|

Products available for sale |

25.45 |

23.55 |

21.33 |

(2.22) |

(9.4) |

|

Purchases of refined products and change in inventories |

3.22 |

3.35 |

4.42 |

1.07 |

31.9 |

|

Products transferred to operations outside Italy |

(1.77) |

(2.36) |

(1.85) |

0.51 |

21.6 |

|

Consumption for power generation |

(0.89) |

(0.75) |

(0.55) |

0.20 |

26.7 |

|

Sales of products |

26.01 |

23.79 |

23.35 |

(0.44) |

(1.8) |

|

OUTSIDE ITALY |

|

|

|

|

|

|

Refinery throughputs on own account |

4.96 |

5.12 |

4.82 |

(0.30) |

(5.9) |

|

Consumption and losses |

(0.23) |

(0.23) |

(0.22) |

0.01 |

4.3 |

|

Products available for sale |

4.73 |

4.89 |

4.60 |

(0.29) |

(5.9) |

|

Purchases of refined products and change in inventories |

12.51 |

17.29 |

13.69 |

(3.60) |

(20.8) |

|

Products transferred from Italian operations |

1.77 |

2.36 |

1.85 |

(0.51) |

(21.6) |

|

Sales of products |

19.01 |

24.54 |

20.14 |

(4.40) |

(17.9) |

|

Refinery throughputs on own account |

31.96 |

30.01 |

27.38 |

(2.63) |

(8.8) |

|

of which: refinery throughputs of equity crude on own account |

6.54 |

6.39 |

5.93 |

(0.46) |

(7.2) |

|

Total sales of refined products |

45.02 |

48.33 |

43.49 |

(4.84) |

(10.0) |

|

Crude oil sales |

32.10 |

36.56 |

43.96 |

7.40 |

20.2 |

|

TOTAL SALES |

77.12 |

84.89 |

87.45 |

2.56 |

3.0 |

In 2013, work continued at the Sannazzaro de’ Burgondi Refinery for the construction of the first industrial plant employing EST (Eni Slurry Technology). As compared to available refining technologies, EST does not produce by-products but converts feedstock completely into distillates and allows to make valuable use of distillation residue of heavy and extra-heavy crude and non conventional resources. An evaluation process and for the exploitation of heavy crude of licensing out of this technology to a number of Oil companies for the application of EST in their productive processes is ongoing.

In addition, Eni is developing the conversion technology by means of Slurry Dual Catalyst (an evolution of EST) that is based on the combination of two different catalysts which could lead to a relevant breakthrough in the EST process, improving products quality and reducing operating costs.

In addition at the Sannazzaro Refinery the detailed design of a project for the production of hydrogen by means of the proprietary Hydrogen SCT-CPO (Short Contact Time-Catalytic Partial Oxidation) process is nearing completion. This reforming technology transforms gaseous and liquid hydrocarbons (also derived from biomass) into synthetic gas (carbon monoxide and hydrogen) at competitive costs.

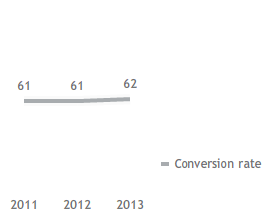

Refinery throughputs on own account and conversion rate (mmtonnes)

In 2013 Eni commenced effectively the industrial project “Green Refinery” that will led the Venice Refinery to be the first example of conventional refinery converted in biorefinery. The related works started in September 2013 while their termination is expected within March 2014, with the start-up of the new biorefinery. The realization of this project is also supported by the industial use of the technology Ecofining developed in partnership with the American company UOP.

In 2013 Eni continued the development of technlogies aimed at reducing the environmental footprint of refining activities and producing more environmental sustainable products. Among the main activities were:

- the development of the proprietary catalytic system for hydrocracking and dearomatization of gasoil T-Sand for the production of high quality diesel, with low quantities of polyaromatics and reducted emissions of particulate;

- the studies on the technologies Zero Waste, a technology for reduction of industrial sludge through a pyrolisis/gasification and inertisation process. Considering the relevance of the projects in the next months the first 2 t/h prototype will be realized in the Gela Refinery;

- the test on Biodiesel from microalgae performed on the pilot plant of Gela. During the experimental phase were tested and individuated types of microalgae providing good performance at high temperatures (summer periods), and low temperatures (winter period) as well as achivied relevant progresses on an innovative process of lipid extraction; the testing activity for the upgrading of the obtained lipids by this process aimed to produce oil to be treated in GreenDiesel technology plant is ongoing.