Activities – Refining

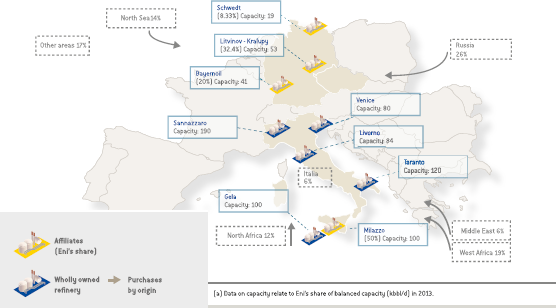

Eni, through its Refining & Marketing Division, is a leader in refining in Italy, with its five wholly-owned refineries (Sannazzaro, Livorno, Venice, Taranto and Gela), and in marketing of petroleum products. In the rest of Europe Eni also holds interests in certain refining poles and is active in retail and wholesale sales in Central-Eastern European countries.

Eni’s refining system has balanced capacity of approximately 39.3 mmtonnes (equal to 787 kbbl/d) and a conversion index of 62%.

In 2013, total refinery throughputs were 27.38 mmtonnes, of which 22.56 mmtonnes in Italy and 4.82 outside Italy. Total throughputs in wholly-owned refineries were 18.99 mmtonnes, down by 1.85 mmtonnes or 8.9% from 2012. This determined a refinery utilization rate of 66%, down by six percentage points from 2012, consistently with negative scenario. Approximately 23.7% of processed volumes were supplied by Eni’s Exploration & Production Division, up by 0.9 percentage point from 2012 (22.8%).

Italy

Eni’s refining system in Italy is composed of five wholly-owned refineries and a 50% interest in the Milazzo refinery. Each of Eni’s refineries in Italy has operating and strategic features that aim at maximizing the value associated to the asset structure, the geographic location with respect to end markets and the integration with Eni’s other activities.

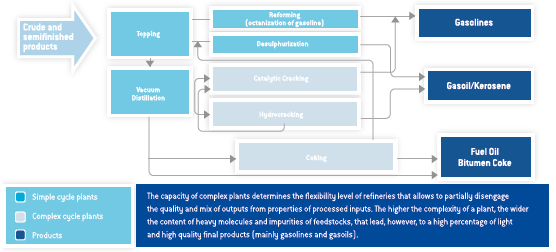

Crude oil that needs to be carried to the refinery by means of pipelines or over long distances by tanker ships undergoes processing for the separation of its components. In refineries crude oil is warmed to a temperature of approximately 400°C so that it turns into vapour. Oil vapours are injected in fractionating columns, also called distillation towers, where they flow upward through a series of plates and cool. At various temperatures they condense and return to a liquid state. While cooling and falling they separate in various hydrocarbon fractions (gasoil, kerosene, naphtha, gasoline, methane, ethane, propane and butane, fuel oil, lubricants, paraffin, wax and bitumen).

|

Refining system in 2013 |

|||||||||||||||||

|

|

Ownership share |

Distillation |

Distillation |

Primary |

Conversion index |

Fluid |

Residue |

Go-Finer/ |

Mild Hydrocracking/ |

Visbreaking/ |

Coking |

Distillation |

Balanced |

||||

|

|

(%) |

(mgl bbl/g) |

(mgl bbl/g) |

(mgl bbl/g) |

(%) |

(mgl bbl/g) |

(mgl bbl/g) |

(mgl bbl/g) |

(mgl bbl/g) |

(mgl bbl/g) |

(mgl bbl/g) |

(%) |

(%) |

||||

|

|||||||||||||||||

|

Wholly-owned refineries |

|

685 |

685 |

574 |

68 |

69 |

35 |

37 |

66 |

89 |

46 |

61 |

66 |

||||

|

Italy |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Sannazzaro |

100 |

223 |

223 |

190 |

73 |

34 |

13 |

|

51 |

29 |

|

74 |

87 |

||||

|

Gela |

100 |

129 |

129 |

100 |

142 |

35 |

|

37 |

|

|

46 |

22 |

29 |

||||

|

Taranto |

100 |

120 |

120 |

120 |

72 |

|

22 |

|

15 |

38 |

|

65 |

65 |

||||

|

Livorno |

100 |

106 |

106 |

84 |

11 |

|

|

|

|

|

|

73 |

92 |

||||

|

Venice |

100 |

107 |

107 |

80 |

20 |

|

|

|

|

22 |

|

44 |

37 |

||||

|

Raffinerie partecipate (b) |

|

874 |

245 |

213 |

47 |

167 |

25 |

|

99 |

27 |

|

79 |

84 |

||||

|

Italy |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Milazzo |

50 |

248 |

124 |

100 |

60 |

45 |

25 |

|

32 |

|

|

77 |

83 |

||||

|

Germany |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Vohburg/Neustadt (Bayernoil) |

20 |

215 |

43 |

41 |

36 |

49 |

|

|

43 |

|

|

92 |

92 |

||||

|

Schwedt |

8.33 |

231 |

19 |

19 |

42 |

49 |

|

|

|

27 |

|

95 |

94 |

||||

|

Czech Republic |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Kralupy and Litvinov (Ceska’ Rafinerska) |

32.4 |

180 |

58 |

53 |

30 |

24 |

|

|

24 |

|

|

78 |

78 |

||||

|

TOTAL |

|

1,559 |

930 |

787 |

62 |

236 |

60 |

37 |

165 |

116 |

46 |

72 |

71 |

||||

Sannazzaro: with a balanced primary refining capacity of 190 kbbl/d and a conversion index of 72.8%, it is considered one of the most efficient in Europe. It is located in the Po Valley and supplies mainly the markets of North-Western Italy and Switzerland. A high degree of flexibility of Sannazzaro refinery allows it to process a wide range of feedstock. With regards to logistics, this refinery is located on the route of the Central Europe Pipeline, which links the Genoa terminal with French-speaking Switzerland. Sannazzaro refinery is provided with two primary distillation plants and related facilities, including in particular three desulphurization units. Conversion is performed through a fluid catalytic cracker (FCC), two hydrocrackers (HdCK) that enable middle distillate conversion (one of them started up in 2009) and visbreaking thermal conversion unit with a tar gasification plant (heavy residue from visbreaking) which produces syngas for the nearby EniPower power station at Ferrera Erbognone.

In October 2013, Eni started-up at Sannazzaro the first conversion plant employing the Eni Slurry Technology (EST), with a 23 kbbl/d capacity. The plant processes extra heavy crudes with high sulphur content and produces high quality middle distillates (in particular gasoil), reducing the yield of fuel oil to zero. Moreover, the Short Contact Time-Catalytic Partial Oxidation project for hydrogen production is underway. In addition, Eni is developing a conversion technology by means of Slurry Dual Catalyst (an evolution of EST) that is based on the combination of two nanocatalysts and could contribute to the breakthrough of the EST technology, improvement of product quality, reduction of expenditure and operating costs. At the Sannazzaro Refinery, the detailed design of a project for the hydrogen production employing the proprietary technology Hydrogen SCT-CPO (Short Contact Time-Catalytic Partial Oxidation) is nearing completion. This reforming technology transforms gaseous and liquid hydrocarbons (also derived from biomass) into synthetic gas (carbon monoxide and hydrogen) at competitive costs.

Taranto: the refinery has balanced primary refining capacity of 120 kbbl/d and a conversion index of 72%. This refinery can process a wide range of crudes and other feedstock. It processes most of the oil produced in Eni’s Val d’Agri fields (2.87 mmtonnes in 2013) and transported to Taranto through the Monte Alpi pipeline. Complex cycles are achieved through a Residue Hydroconversion Unit (RHU) - Hydrocracking process and a “Two Stage” Visbreaking - Thermal Cracking unit.

Gela: the refinery has balanced primary refining capacity of 100 kbbl/d and a conversion index of 142%. Gela refinery represents an upstream integrated pole with the production of heavy crude oil obtained from nearby Eni fields in Sicily, while downstream it is integrated with Eni’s nearby petrochemical plants. Located on the Southern coast of Sicily, it mainly produces fuels for automotive use and other feedstock. Its high conversion level is ensured by a catalytic cracking unit integrated with go finer for feedstock upgrading and two coking plants enabling conversion of heavy residues topping or vacuum residues. The power plant of this refinery also contains modern fume treatment plants (so-called SNOx) which allow full compliance with the tightest environmental standards, removing almost all sulphur and nitrogen composites coming from the coke burning-process.

In 2013 Eni launched a project for the renovation and recovery of the Gela refinery. The refinery will be able to generate profits through the maximization of diesel production and the interruption of gasoline and polyethylene production and will enhance its eco-compatibility. In particular, the project provides for the closing of gasoline (FCC and ancillary) and polyethylene lines as well as the conversion of go finer in hydrocracking.

Livorno: the refinery has balanced primary refining capacity of 84 kbbl/d and a conversion index of 11%. It produces mainly gasoline, gasoil, fuel oil for bunkering and lubricant bases. The refinery includes, beyond the primary distillation plants, two lubricant manufacturing lines. The refinery is connected with Livorno’s docks by highways, railways and oil pipeline, while it is connected with the Florence storage sites by two pipelines, permitting to optimize intake, handling and distribution of products.

Venice: the refinery, with balanced primary refining capacity of 80 kbbl/d and a conversion index of 20%, supplies mainly markets of North-Eastern Italy and Austria. In September 2013, Eni started its conversion into a bio-refinery, with an objective of mechanical completion by the end of the year and the production start-up in April of 2014. The conversion exploits an established proprietary technology (Ecofining) for the production of innovative bio-fuels, with lower environmental impact (reduced emissions of particulate) and higher motoring efficiency, exceeding technical limits of bio-fuels mixture currently present on the market. Ecofining technology is flexible with regard to the raw material, capable to convert the second-generation feedstock (exhausted vegetable oils and animal grease) which are not in competition with alimentary chain.

Milazzo: : jointly-owned by Eni and Kuwait Petroleum Italy, the refinery has balanced primary refining capacity of 100 kbbl/d (Eni’s share) and a conversion rate of 60%. Located on the northern coast of Sicily, it is provided with two primary distillation plants, one unit of fluid catalytic cracking (FCC), one hydrocracking unit for the conversion of middle distillates (HdCK) and one unit devoted to the residue treatment process (LC-Finer).

Outside Italy

In Germany, Eni holds an 8.3% interest in the Schwedt refinery and a 20% interest in Bayernoil, an integrated pole that includes Vohburg and Neustadt refineries. Eni’s refining capacity in Germany amounts to approximately 60 kbbl/d, mainly used to supply Eni’s distribution network in Bavaria and Eastern Germany.

Eni holds a 32.4% stake in Ceska Rafinerska, which owns and operates two refineries in the Czech Republic, Kralupy and Litvinov. Eni’s share of balance refining capacity is about 53 kbbl/d.