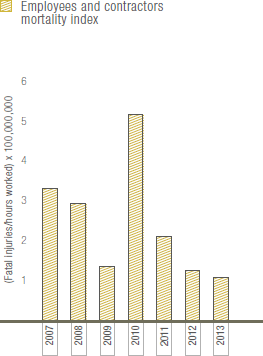

Employees and contractors mortality index

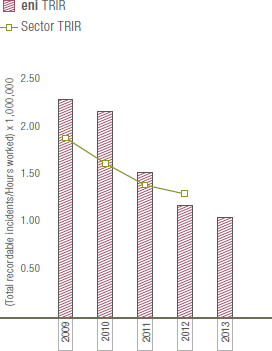

eni TRIR vs sectoral TRIR

Source: eni documents based on the public documentation of a panel of competitors.

From an operational point of view, the analysis of near misses as well as accidents and the consequent implementation of corrective actions with regard to procedure or plant design represents an element of continuous improvement.

A separate discussion is required on fatalities in eni which to date still represent the main cause for concern in relation to the company’s performance.

In 2013 there were 6 fatal accidents thereof 4 involving employees of Saipem (in Indonesia, Angola, Saudi Arabia and Brazil) and 2 involving contractors (in Saudi Arabia). Further actions are currently being taken to promote a change in cultural attitudes, particularly for management of operations in cultural contexts where attitudes to safety management fall short of the more stringent international standards.

Process safety and asset integrity are fundamental aspects in the prevention of risks in eni operations.

Process safety is ensured by the correct implementation of all phases, from plant and equipment design to plant and process operation.

Planning and design takes place in line with internationally recognized rules and standards and includes risk analysis by multidisciplinary teams whose observations are taken into account in the plant construction. With regard to operations, activities are conducted in line with the parameters established by the process manuals and by specific operating procedures.

Structural reliability and integrity of the equipment are continuously monitored to ensure high levels of efficiency.

In May 2013 eni took part in one of the most important international events in relation to process safety, the 14th International Symposium on Loss Prevention and Safety Promotion in the Process Industries, presenting best practices in the refinery sector, where a long-term project has been launched to review and update the equipment integrity management system. The aim is to increase the capacity and effectiveness of current methods of preventive and predictive maintenance.